Update: 14 November 2020

Unfortunately, I have not been able to get back to the UK and the car has had no use for nearly a year. The car has done a total of 14,200 miles and hardly any in the last year.

MOT HISTORY.

November 2020 – 14,200 – NOT BOOKED

October 2019 – 14,111 miles – PASS

October 2018 – 13,764 miles – PASS

October 2017 – 12,660 miles – PASS

October 2016 – 12,102 miles – PASS

October 2015 – 11,677 miles – PASS

October 2014 – 11,095 miles – PASS

September 2013 – 10,521 miles – PASS

September 2012 – 10,014 miles – PASS

September 2011 – 9,628 miles – PASS

September 2010 – 9,220 miles – PASS

September 2009 – 8,443 miles – PASS

September 2008 – 7,258 miles – PASS

Update: 4 September 2020. After spending £8000 to have the front and rear suspension refurbished by a Rally Prep company in Witney, Oxfordshire.

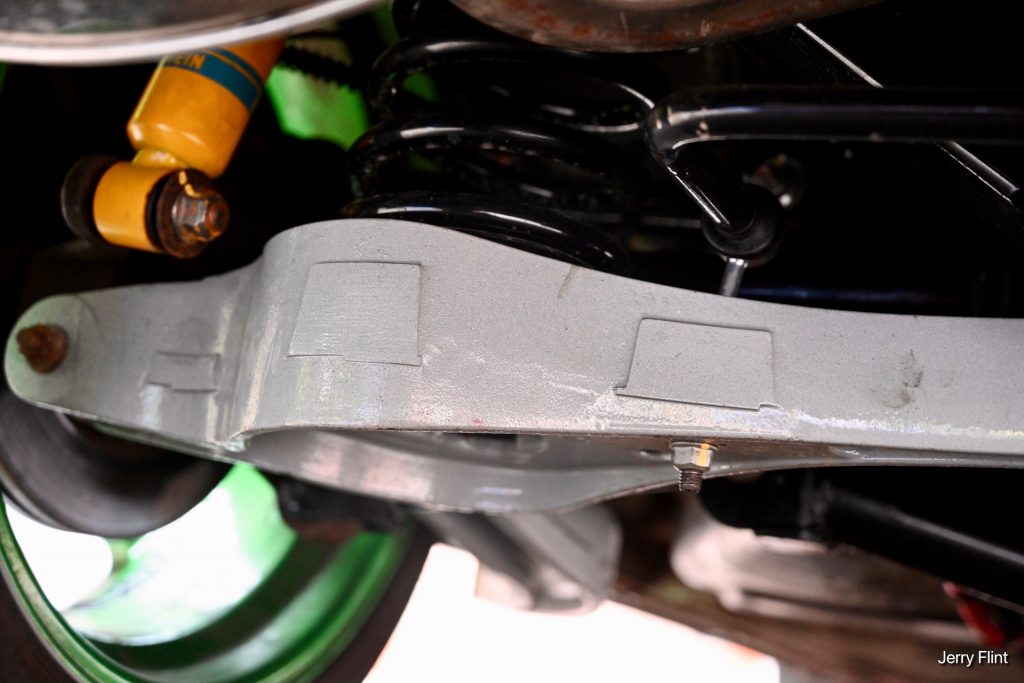

I discovered by accident that the rear trailing links were reattached to the underside of the car incorrectly, making it sit far too high. The company did have problems aligning the car and this explains the reason why, in that the links affected the suspension geometry substantially. The company blamed the uprated lateral links causing difficulties in alignment, in fact it was the incorrect location of the trailing ams that caused the problem. To make it 100% it really needs another alignment, which will be done when Mot’d.

First three pictures depict how it was returned from Rally Prep company and the last three how it looks today, third from left you can see the link and fourth from left it’s miraculously gone.

The links are now fitted correctly and all that is needed is a further check of the alignment.

Below is the data sheet from Vehicle Handling Solutions. http://VehicleHandlingSolutions.com

[dg ids=”28305″]

Still have the following parts to fit. Blaster ignition coils, illuminated kick plates, silicone engine compartment hoses and sundry stainless steel parts. Will get a garage to fit the new flexible brake hoses (RPS Rally dod not fit). Only upgrade considering is new ICE (Alpine if I do it). New drivers wiper blade fitted as it was installed upside down and the plastic broke when removed (age fatigue). I will have the 19 inch green wheels refurbed, thinking of the same finish as the refurbed Apex’s have.

Update: 24 December 2019. New kick plates delivered ready for fitment. Plus a full set of engine hoses from Classic Silicone Hoses. For more details click here.

Gallery below: 20 September 2019, MG centre cap are now fitted.

Number 879 of 883 is the last Monogram ZT260 SE made and is the only Mk2 facelift ordered with the supertallic biomorphic green paint.

It is 15 years old and has covered 14,050 miles!

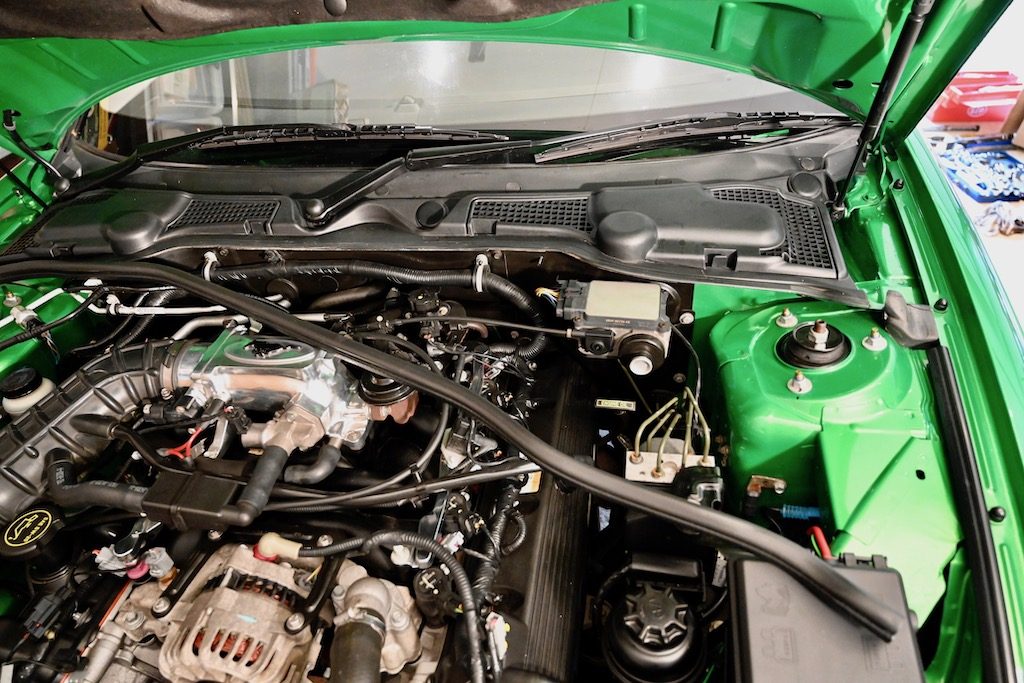

Modifications, include genuine XPower side skirts and rear spats, an Accufab throttle body, XPower exhaust and a K and N air filter.

Update: 22 September 2019.

I removed the sleeves from the XPower exhausts which required the back boxes to be removed from the car to extract the sleeve.

Update: 10 September 2019

The green machine (ZT260 V8) returns from RPS Rally after having subframes powder coated and replacement links fitted. New brakes parts were fitted were appropriate, hand brake cables, exhaust parts, drop links, suspension bushes and Bilstein shocks.

Apex are now fitted to the car after being refurbed and new tyres fitted by Platinum Alloys of Swindon.

Update: 24 June 2019

The car is currently at RPS Rally having both sub frames powder coated. Once done it will be rebuilt with new Bilstein Shocks, brakes, all new bushing and brakes. Only negative is that the wheels are still green.

Update: 22 February 2019

Ordered recently the following from – Austin Garages Rear Anti-Roll Bar kit, Rear Link bolt kit and Brake pads. Nick from Austin Garages mentions the brake adjusters ordered below are not for the ZT260.

Plus upgraded rear link bushes from Powerflex

Powerflex Rear Upper Lateral Arm Inner Bushes – ZT 260 (2001-2005) – PFR42-411

Powerflex Rear Lower Lateral Arm Inner Bushes – ZT 260 (2001-2005) – PFR42-410

Update: 20 February 2019

I followed a very informative thread on the two-sixty website on how to change the Heater Valve.

Basically:

- Set the heater to full cold before starting work (I checked mine and it was functioning normally).

- Remove bonnet seal trim.

- Remove wiper arms.

- Using a small screwdriver, lift out the scuttle clips protecting the scuttle with a cloth. Keep you hand over the clips to prevent them flying off.

- Remove the covers over the brake reservoir and the heater valve plenums. Below each of these you will see a plastic fixing which needs to be removed.

- Remove the cover located over heater plenum.

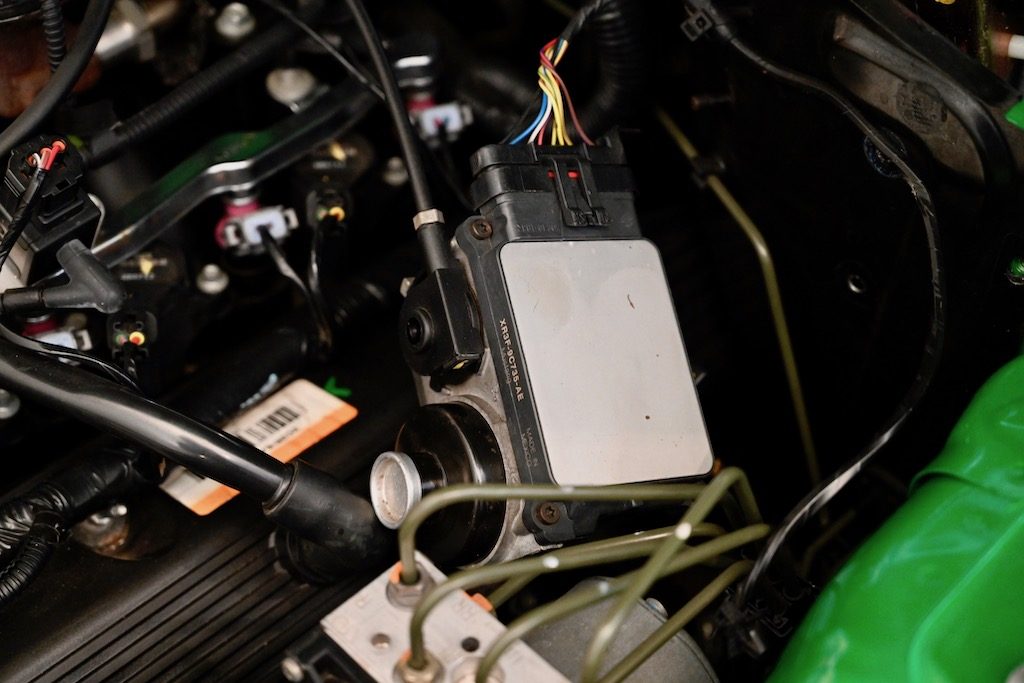

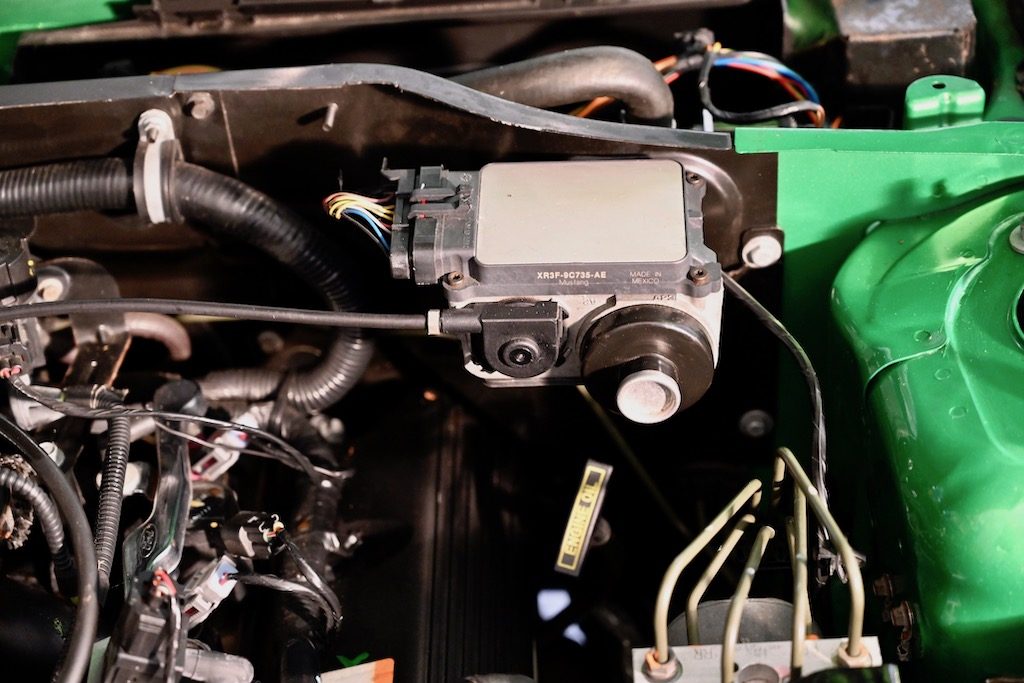

- Displace the Electronic throttle to give you access to the nuts that release the Heater Valve.

- Replace all components and reverse the procedure.

_________________________

Update: 19 February 2019

I am about to replace the heater hose (260 club supplied) as a precaution and the Pollen Filter (supplied by DMGR). I was debating whether to replace the club supplied heater valve at the same time. Then I remembered my first ZT260 was terrible in the early days. I did 16,000 miles in 10 months and it was in Kernahan shop being fixed for 2 months because the AC was uncontrollable. Will also replace the spring clips with stainless clips supplied by Westfield Fasteners. Pictures to follow.

Ordered from DMGR:

2 x Rover 75 / MG ZT Brake Shoe Fitting Components – Springs, Pins, Adjusters – SXS100000, SXR100010, SMN100290, SMN000140 – Springs and Pins – SMN100290 and SMN000140

2 x Rover 75 / MG ZT Brake Shoe Fitting Components – Springs, Pins, Adjusters – SXS100000, SXR100010, SMN100290, SMN000140 – Adjuster – SXS100000

2 x Genuine Strut Top Mount and Bearing – Rover 75 / MG ZT – RNX100080 / RNX100081 – Strut Top Mount inc Bearing

1 x MG ZT260 / Rover 75 V8 Auxiliary Drive Belt – PQS000300 / PQS000301 – Dayco

1 x Genuine Ford ZT260 / 75 V8 Oil Filter – LPW000070 / LPW000071 MG Rover

1 x MG ZT260 / Rover 75 V8 Rear Brake Shoes – PAGID SFS000070

1 x Rover 75 / MG ZT Ultimate Undertray Fixing Kit (Bolts and Clips) KZM000040 & KZM000050 – 10x Bolts, Clips and Penny Washers

1 x 75 / ZT Pollen / Cabin Filter – Genuine MG Rover – JKR000030 / JKR000031

Update: 11 February 2019

I’ve had my BMW 435D for 21 months and until 2 months ago it had only done 1300 miles. Today that figure is 3400 miles. I have to say the bloody thing is amazing. The torque on pick-up is truly fantastic and it doesn’t slip slide around as it is fitted with X-drive (4wd). One of the great things it has is a head display which should be standard on all cars. Oh and the fuel consumption is sensible.

Today, I took out the Green monster, for the first time since I bought it last year and drove it a very short distance as its SORN (drove on a private – unadopted road) and the thing is a cart horse in comparison. I kind of like it, but it is so sluggish in pick-up and its acceleration compared to the 435D feels very slow. To top it off the EMG illuminated, which I could do without.

Anyway, it was washed and then returned to the garage. I subsequently ordered the club heater valve today and some stainless JCS – HiGrip clamps (like jubilee). I will then fit this and the new heater hose previously ordered at the weekend if the heater valve arrives. Plus I will fit the DRL fogs this weekend too (or at least thats the plan).

Next job will be the Bilstein shocks when they arrive (with possibly new club discs and links fitted with power flex). Unsure whether I will keep it. There’s nothing wrong with it, but it doesn’t excite me as I thought it would.

One last comment are the wheels, has anyone fitted Vossen wheels? I think this style would suit the ZT260.

Update: 21 January 2019

Ordered today the following from an Ebay garage – Austin Garages.

Roof Rail grommet (£9.99) and rear sub frame bolts (£25.00).

Update: 15 January 2019

Changed a few of the fixings under the bonnet to stainless.

Update: 22 November 2018

As I have been away, not sourced many components yet, only because it doesn’t need much. Bought a trickle charger that is permanently fitted to the car. Refitted the missing rear badges to the boot lid.

Ordered some new Bilstein shocks and next are upgraded brake discs (again not necessary). Bilsteins ordered from TwoSixties at a cost of £1008. Upgraded brake discs from the same source are £395.

Also ordered from the same source a new top heater hose (£40.60) and oil sump drain (£5.80).

The first order was a Petrol Filter Clip Kit WJC000230 with the essential VITON Seal ordered from BizzyLizzy priced at £9.99 Fitting Guide for Clip.